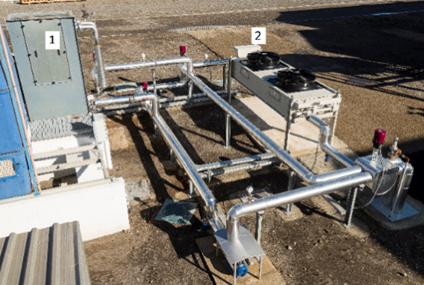

This test bed consists in three circuits: cooling circuit, exchange circuit and heating circuit. In the cooling circuit, water circulating inside the tube bundle of a Surface Condenser is cooled either through a Wet Cooling Tower (1) or an Air Heat Cooled Exchanger (2), both with a thermal power of 200 kWt at nominal conditions. In the exchange circuit, a Steam Generator (80 kWt) produces steam at different pressures (between 80 and 200 mbar), that is in turn condenses in the Surface condenser (80 kWt), transferring its latent heat to the cooling water that is heated. Finally, in the heating circuit, a static solar field of 300 kWt (at design) provides the thermal energ to the Steam Generator in the form of hot water.

(a) |

(b) |

(c) |

|

Cooling circuit (a), exchange circuit (b) and heating circuit (c) in the hybrid cooling systems test bed

The Multi-effect Distillation (MED) pilot plant is a vertically stacked unit composed of 14 stages with direct water supply in the first effect (forward feed configuration). The distillate production at nominal conditions is 3 m3/h with a feed water flow rate of 8 m3/h for which a total thermal power of 190 kWt is required. The temperature lift between the first and last stage is 40 °C at nominal conditions with a Top Brine Temperature (the maximum brine temperature that takes place in the first stage) of 70 °C. The hot water supplied to the first effect comes from the same static solar field described in the hybrid cooling systems test bed.

(a) |

(b) |

MED unit (a), static solar field (b)